What is a UV Cured Adhesive

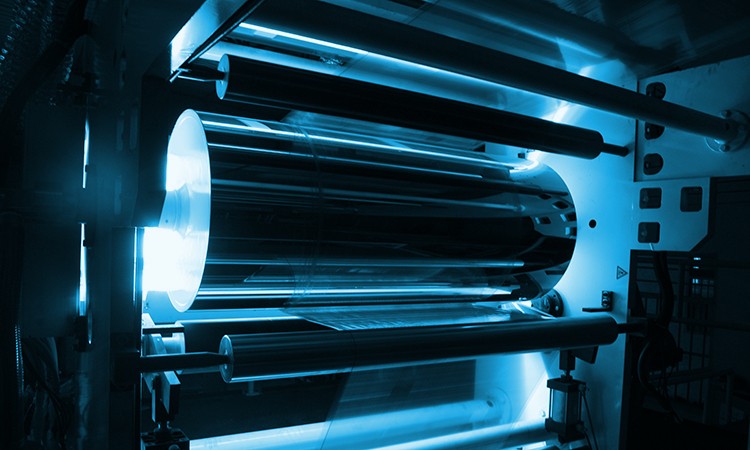

UV cured adhesives are a blend of 100% solids acrylic polymers that feature a low molecular weight before coating. This allows for a solvent- and water-free “warm melt” coating process. During the coating process, these adhesives are heated to a temperature between 130 to 140°C (266 to 284°F); a lower temperature than required for traditional hot melt adhesives that allows for coating in a similar manner. Once the adhesive has been coated, it is then exposed to a specific range of UV radiation to crosslink the polymer chains and build molecular weight. This crosslinking builds adhesive performance and transforms the polymers into a usable, functional pressure-sensitive adhesive.

Adhesive Performance

UV cured PSAs share many common characteristics with solvent-based adhesives. With the exception of a lower shear level, the adhesive performance tends to be similar to traditional solvent-based adhesives. In addition, these adhesives also offer a good resistance to heat, moisture and chemicals, although not to the level of a solvent-based adhesive.

The main benefit of these UV adhesives over solvent-based adhesives is extremely low levels of VOCs and odors. Since they are made without solvents or other potentially hazardous process aids, they are a particularly good fit for applications in strict regulatory environments like medical or automotive applications.

In addition to standard adhesives, the challenging nature of UV cured PSA applications often requires specifically formulated, customized adhesive solutions. Working closely with our customers, our scientists and engineers can quickly adjust existing adhesive platforms or develop new polymer systems to address the most complex challenges.