Design flexibility is paramount in automotive mounting, assembly and fixation applications. Industry trends like the increased use of plastics and a greater need for bonding dissimilar materials present a variety of bonding challenges that can be demanding for pressure-sensitive adhesives. Adhesive selection can be challenging for these applications with conditions which range from extreme temperatures to the presence of oils and chemicals, low surface energy (LSE) materials to strict OEM specifications and requirements.

While no adhesive can be used for every application in automotive, Avery Dennison’s S8764 is an all-around adhesive that can be selected for a wide range of automotive applications. Used in pressure-sensitive tapes for door panels and trim, flexible surfaces like seating and headrests, noise and vibration damping and HVAC systems. Due to the versatility of S8764 it has been used in pressure-sensitive label applications, including underhood warning labels, battery labels and labels for LSE plastic surfaces.

As a high solids, acrylic adhesive, S8764’s performance characteristics make it an ideal solution for many automotive applications:

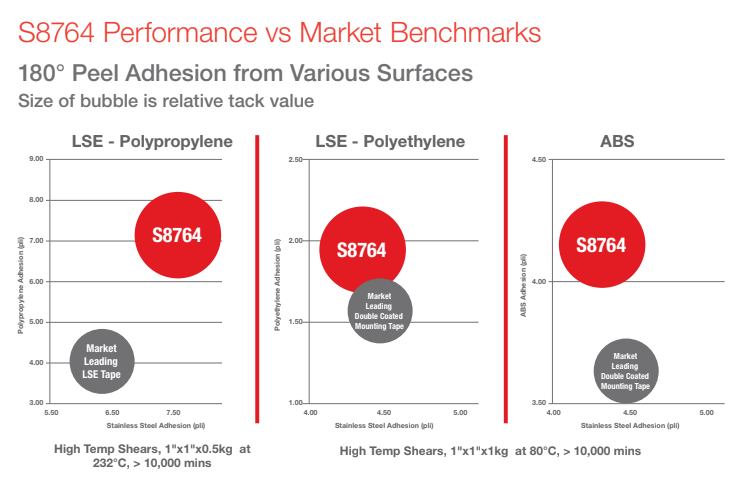

- Aggressive tack and quick wet out for high immediate adhesion to many surfaces – including closed cell foams, LSE plastics and metals

- High shear performance, providing high temperature resistance and good converting performance with little edge ooze

- Adhesion to oily surfaces, requiring less surface preparation before application

- Chemical and humidity resistance for lasting performance in harsh environments

- High solids content, resulting in lower applied costs by enabling high speed coating and converting

- Tested to be compliant with Toyota TSK6712G and Ford WSS-M11P62-A specifications